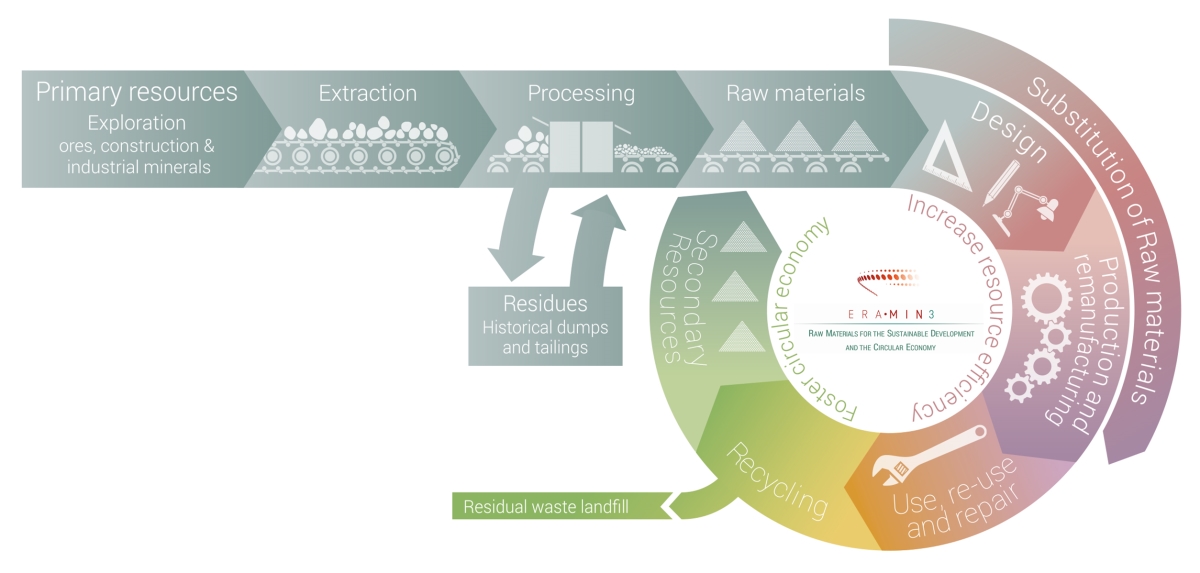

ERA-MIN: Raw Materials for the Sustainable Development and the Circular Economy

ERA-MIN Pan-European networks represent a prominent examples of public-public partnerships (P2P) within the landscape of the European Research Area . Its primary objective is to coordinate research and innovation (R&I) funding programmes and foster collaboration among public research funding organisations, namely ministries, funding agencies, and programme managers, from both European Union (EU) Member States countries and regions, EU Associated Countries and other nations worldwide.

The ERA-MIN Dashboard is an interactive map of R&I funded projects that allows you to navigate interactively through each and every one of the projects and group them by: i) country and find information about applicants involved, allocated funding, and average funding per project; ii) categories of the ERA-MIN Research Agenda (2013); iii) mineral category (ores and metals, industrial minerals or construction materials); and iv) project keywords.

ERA-MIN networks intend to complement existing financing instruments, such as Horizon 2020, Horizon Europe, and EIT Raw Materials, by initiating joint calls for transnational R&I projects that address the specific requirements of the raw materials research community. The specific emphasis on the bottom-up methodology, low Technology Readiness Levels (TRLs) ranging from 1 to 5/6, and the formation of small transnational consortia provide a distinctive prospect for the collaboration of highly skilled research groups between the European Union (EU) countries and regionsand countries outside Europe.

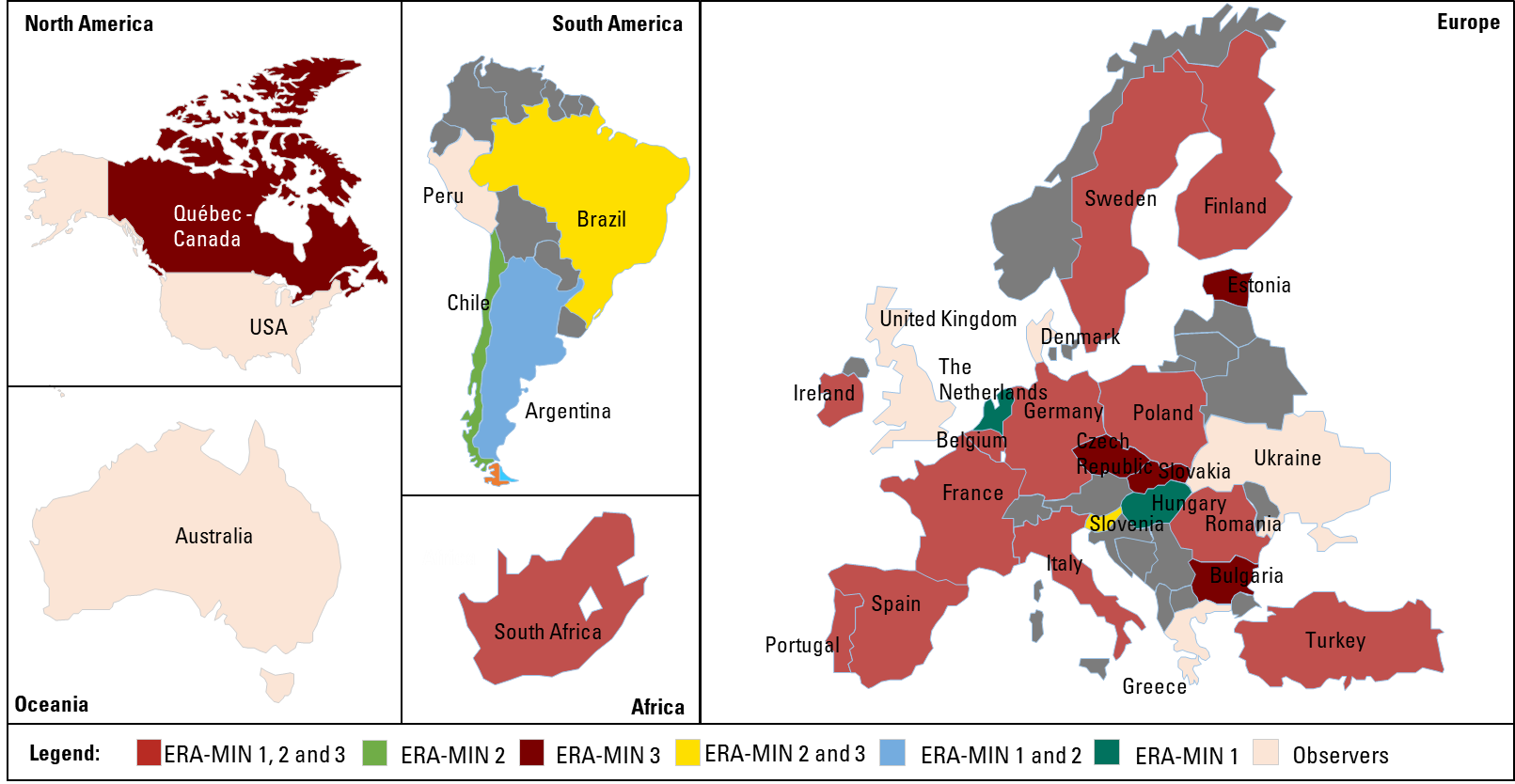

The ERA-NET Co-fund on Raw Materials (ERA-MIN3) is a global, innovative, and flexible pan-European network of 25 public research funding organisations that is currently in its third edition and supported under Horizon 2020. ERA-MIN3 (2020-2025) builds on the experience of the H2020 ERA-NET, ERA-MIN 2 (2016-2022), and the FP7 ERA-NET ERA-MIN (2011-2015).

All three ERA-MIN pan-European networks have aimed to support the Strategic Implementation Plan of the European Innovation Partnership on Raw Materials (EIP RM), the EU Raw Materials Initiative, and further develop the raw materials (RM) sector in Europe through funding of transnational R&I activities. This has been achieved through joint transnational calls designed and developed specifically for the non-fuel, non-food RM sector, specifically the primary and secondary of metallic, construction, and industrial minerals.

The 3 ERA-MIN networks have implemented eight joint transnational calls in total and have supported a total of 88 R&I projects with €93 million of total costs and €68 million of public funding, including €10 million of EU contribution in Horizon 2020. More than 40 R&I projects have reached their end, and to promote the uptake of research outcomes, the final project summaries are available on the website. (See dashboard above)

Since 2011, the 3 ERA-MIN pan-European networks have counted on the formal participation of 24 different countries and 4 EU MS regions. Currently, there are 20 countries/regions actively involved in ERA-MIN3, including 15 EU Member State countries, 3 EU MS regions, one EU Associated Country, and 3 countries outside Europe (Brazil, Québec Province, Canada, and South Africa), with an additional 11 EU and non-EU countries, including Argentina, Australia, Chile, Peru, the UK, Ukraine, the US, and 6 EU regions acting as observers or invited partner countries and regions.

One of ERA-MIN's long-term goals is to continue expanding its formal membership and broadening the reach of its calls, which have included the participation of entities from over 27 different EU and non-EU countries and 9 EU regions.

Examples of selected projects

|

Project title |

New concepts for efficient extraction of mixed rare earths oxides from monazite concentrates and their potential use as dopant in high temperature coatings and sintered materials |

|

Project start date (day/month/year) Project end date (day/month/year) |

01/05/2018 31/10/2021 |

|

Project website |

|

|

Consortium Coordinator |

NATIONAL RESEARCH AND DEVELOPMENT INSTITUTE FOR NONFERROUS AND RARE METALS, 102 Biruintei Blvd., Pantelimon, ROMANIA |

|

Project Partners |

Italian National Agency for New Technologies, Energy and Sustainable Economic Development – ENEA Institute for Chemistry of Condensed Materials ICMCB Bordeaux, France MGM Star Construct srl Bucharest, Romania |

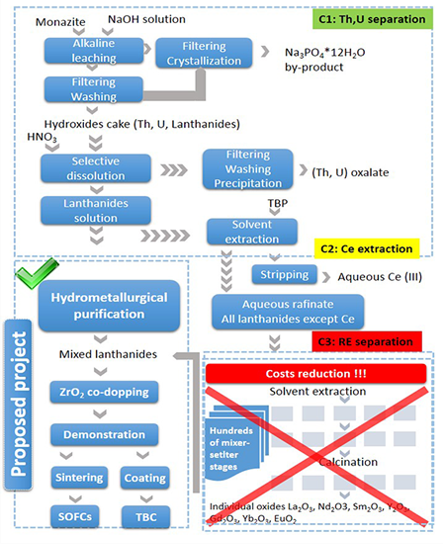

Rare earth elements (REEs) are fundamental elements to promote a critical transition to a carbon-neutral Europe and a decarbonised economy. In current technology, REEs are separated and purified by hundreds of successive extraction operations, making use of organic solvents. The MONAMIX project proposes a new concept and process/product design for increased raw material efficiency by extracting REEs from monazite concentrates and using their natural mix as a dopant for advanced ceramics. This approach can reduce costs by 10-15%, together with a decreased environmental impact of the extraction processes by reducing chemicals and energy consumption.

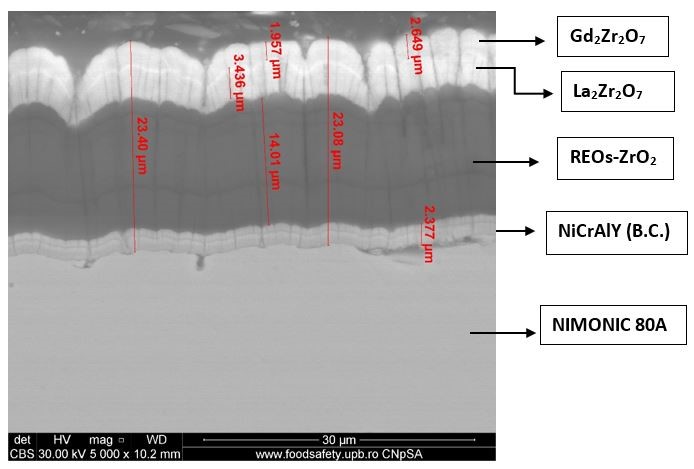

In the MONAMIX project, a mixture of REE hydroxides in natural proportion was used as a dopant in zirconium oxide-based ceramics by means of a green chemistry process. Doped powders with controlled composition and granulation were used to demonstrate their potential for use in two high-tech applications: thermal barrier coatings (TBCs) with the aim of increasing the efficiency of gas turbines in the co-generation of electricity and sintered products for combustion cells with solid electrolytes. Both applications are related to clean energy with minimal greenhouse effects.

The project results are: 1 new technology, 2 new products, 1 Romanian patent request, open access publications, including 5 ISI research papers, and 1 book chapter.

|

Project title |

Circular product design for automotive components made from recycled and sustainable composite material |

|

Project start date (day/month/year) Project end date (day/month/year) |

01/08/2022 31/07/2024 |

|

Project website |

|

|

Consortium Coordinator |

Fraunhofer IGCV, Germany |

|

Project Partners |

Plastic Omnium, France Arkema, France Tallinn University of Technology, Estonia Autefa Solutions, Germany IRT M2P, France Rexhi, Germany Autotech Engineering and Forward Engineering, Spain |

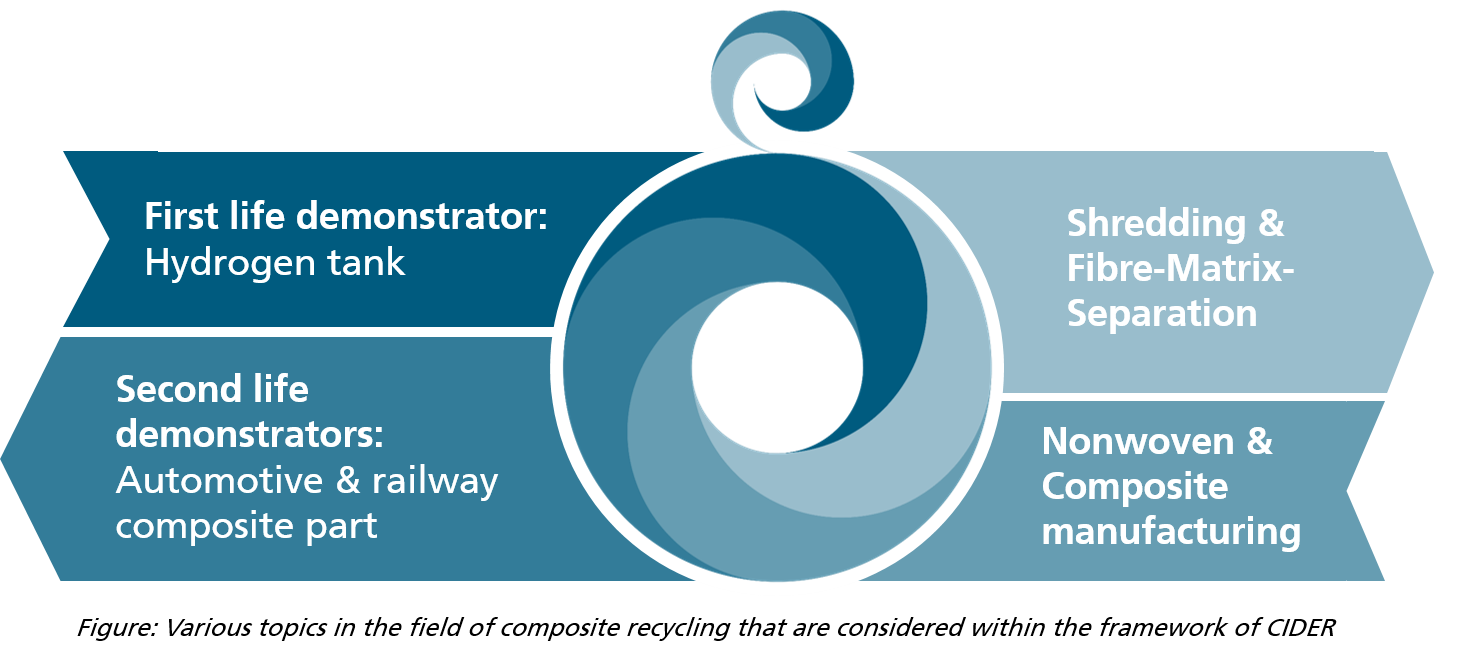

The overall objective of the Cider project is the development of sustainable, recyclable, and recycled composite materials for the transport sector. This will be achieved by developing three demonstrators over multiple life cycles of the fibre and polymer material.

To address future automotive markets, first-life composite structures such as hydrogen tanks (type 4) with carbon fibre reinforcement and Elium® resin will be developed. After prototyping, they will be used to focus on circularity and recycling. Here, the aim is to separate the composite material and reclaim the expensive and energy-intensive carbon fibre as well as the matrix system from it. After the fibre reclamation, an innovative production technique to produce oriented nonwovens will be further developed. Various production and material aspects have to be investigated in order to meet the quality criteria for the second-generation parts. For this purpose, the production of different material combinations is also important in order to determine the material properties by means of non-destructive and mechanical tests. Following this, the development of a circular composite design for the second-life components will be part of the project. In this design approach, recycling options will be considered, as well as a life-cycle analysis (LCA) of the parts, which will be carried out and implemented into the design process. For the final production of the second-life automotive and railway components, the developed oriented nonwovens made from rCF will be used to produce composite parts with the recyclable Elium® resin.

|

Project title |

New sustainability metrics to improve recycling PROcess PERformances regarding resource use, environmental impacts and economic benefits |

|

Project start date (day/month/year) Project end date (day/month/year) |

01/08/2022 31/07/2024 |

|

Project website |

N/A |

|

Consortium Coordinator |

BRGM, Fance |

|

Project Partners |

RDC Environment, Belgium Extracthive Ceramics Recycling, France |

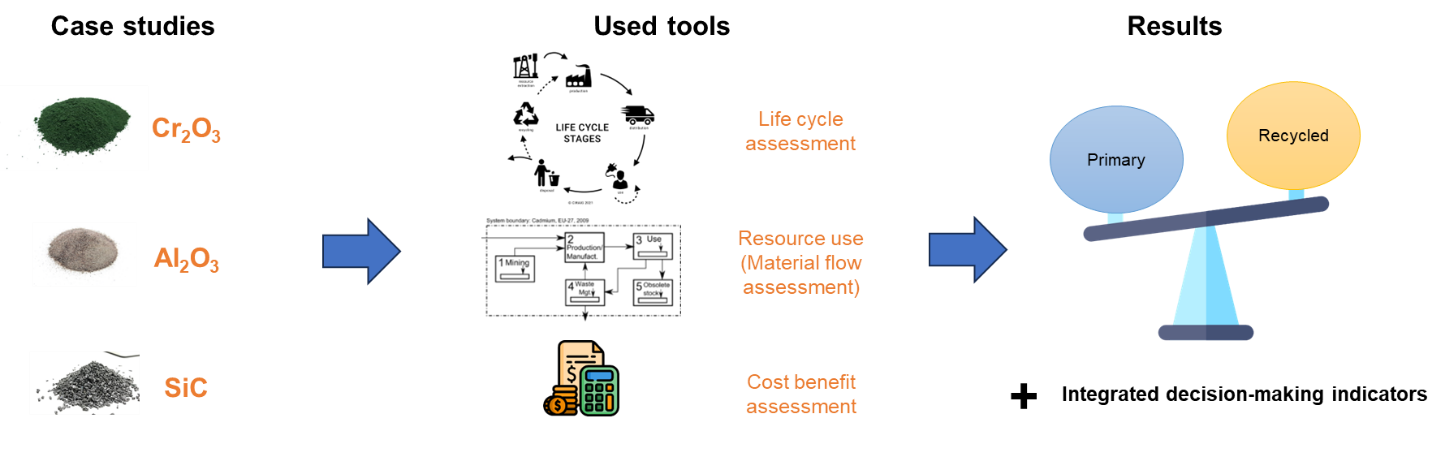

The exploitation of natural resources generates economic development but compromises the associated natural capital and produces environmental impacts. The goal of PROPER is to develop indicators for measuring and improving the resource efficiency of existing and future raw material production processes as a support for companies’ decision-making. Indicators to offer a comprehensive and innovative vision of the resource, environmental, and economic impacts and benefits of processes.

In addition to demonstrating the benefits of secondary production against primary production in three case studies and on the three dimensions mentioned above, the project also developed life cycle inventories for the recycling routes of three refractory powders and applied for the first time resource dissipation methodologies to industrial minerals.

|

Project title |

A novel circular economy for sustainable RE-based magnets |

|

Project start date (day/month/year) Project end date (day/month/year) |

01/05/2018 30/04/2021 |

|

Project website |

http://www.maxycle.eu/ |

|

Consortium Coordinator |

JOSEF STEFAN INSTITUTE; SLOVENIA |

|

Project Partners |

Magneti Ljubljana, d.d., Slovenia OBE Ohnmacht & Baumgärtner GmbH & Co. KG, Germany, Pforzheim University of Applied Sciences, Germany IVL Swedish Environmental Research Institute, Sweden |

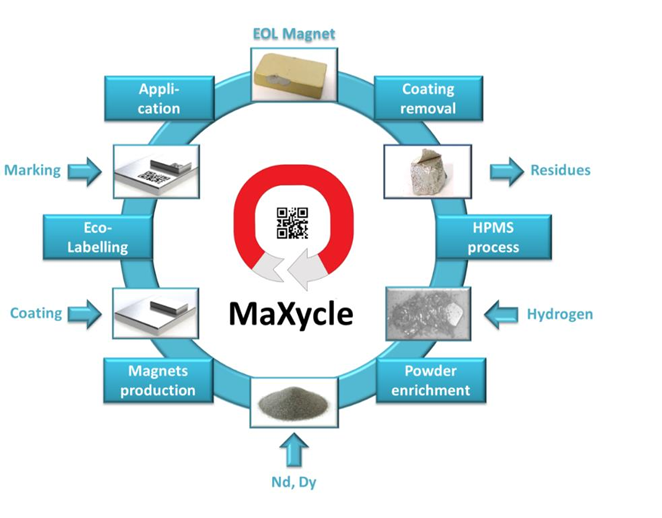

The objective of MaXycle was to establish an environmentally sustainable "short cycle" reprocessing route. The final achievements include:

a) We developed an eco-labelling system for newly manufactured rare earth (RE) permanent magnets. b) We implemented the highly efficient HPMS process, re-processing materials directly from the NdFeB EOL magnets. c) We developed enhanced treatments to eliminate residues from the pre-processing stage. d) We enhanced the magnetic properties of End-of-Life (EOL) NdFeB magnets by customizing the microstructure and phase composition. e) We conducted comprehensive industrial up-scaling, along with a thorough life cycle assessment.

The outcomes of MaXycle are poised to address the challenge of low recycling rates caused by inadequate collection, high material leakage, and suboptimal interface management between logistics, mechanical pre-processing, and metallurgical metal recovery.

Furthermore, advancing the development of recycled RE-based magnetic raw materials holds the potential to create new markets for specialized recycled magnetic products, strengthening competitiveness and driving economic growth.