Air pollution and industrial emissions

Preserving air quality is among the main objectives of the European Union policies on environmental protection. Based on a fitness check of the Ambient Air Quality Directives, the European Green Deal announces for a sustainable industry the adoption of a zero-pollution action plan in 2021 and the proposal to align air quality standards to World Health Organization (WHO) recommendations. To achieve this, monitoring, modelling, and controlling industry emissions play an interconnected key role.

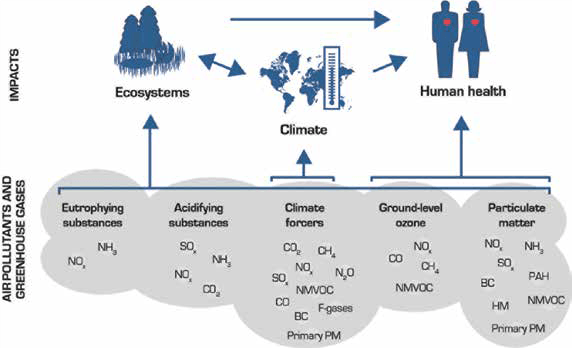

In addition to the release of substances that contribute to global warming, industrial activities also emit pollutants to the atmosphere that can affect air quality. These emissions are associated with impacts on human health and on ecosystems (Figure 1).

BC=black carbon (a typology of particulate matter), CH4=methane, CO=carbon monoxide, CO2=carbon dioxide, F-gases= fluorinated gases, HM=heavy metals, N2O=nitrous oxide, NH3=ammonia, NMVOC=non-methane volatile organic compounds, NOx=nitrogen oxides, PAH=polycyclic aromatic hydrocarbons, PM=particulate matter, SOx=sulphur oxides.

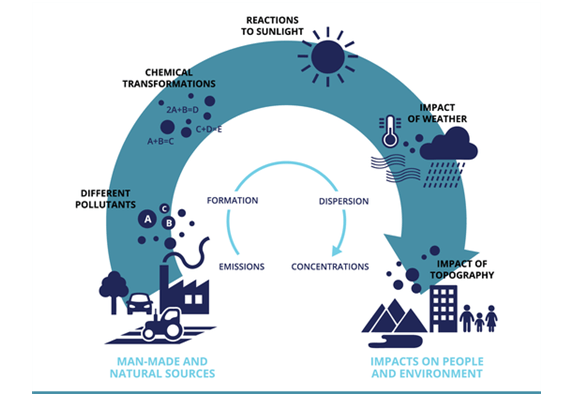

The relationship between air quality and emission of pollutants is complex. Primary pollutants, i.e. pollutants directly emitted by a source, interact with the atmosphere and can form other type of substances, i.e. secondary pollutants, after being in contact with water, sun light, other pollutants, etc. Primary air pollutants include particulate matter, sulphur dioxide, nitrogen (di)oxide, ammonia, volatile organic compounds and methane, while secondary air pollutants are e.g. secondary particulate matter and ozone (EC, Cleaner air for all). In addition, transboundary pollution entering the EU from other northern hemisphere countries is growing, which also has an impact on the concentration of air pollutants.

The ultimate impact of air pollution depends not only on pollutant concentration but also on other variables such as topographic conditions and the possible further transport of primary and secondary pollutants - even for very long distances - (see Figure 2 and EEA). As a result of this complexity, the relationship between volume of pollutants emitted, concentration of air pollutants in the air and pollutants’ ultimate impact is neither linear nor easily predictable.

In addition, noise pollution is a major environmental concern in Europe. This includes also industrial sources of noise, such as extraction and production of non-energy raw materials, with activities like rock loading and unloading, power generation, drilling, transport, etc. The European Environment Agency present in the NOISE Observation & Information Service for Europe data on exposure to different levels of noise from roads, industries, etc.

Air pollution and air quality have been among the main political concerns in the EU since the 1970s. The EU air quality policy aims to establish air quality targets and emission ceilings that are compatible with economic growth and sustainable development, and in line with relevant international conventions.

One of the pillars of the EU air quality policy is the establishment of emissions standards for key sources of pollution. To that aim the Industrial Emissions Directive (IED) requires the adoption of ‘Best Available Techniques’ (BATs) by large industrial installations. This affects industries such as the production of metals, minerals, paper and wood. BATs are specified in the BAT reference documents (BREF), which set reference limit values for the emissions of some substances. BREFs have been already adopted for iron and steel, ferrous metals processing, non-ferrous metals, cement and lime and magnesium oxide, wood-based panels, pulp, paper and board, glass and ceramic. In addition, a reviewed version of the BREF on Management of Tailings and Waste-rock in Mining Activities, whose standards will yet not be binding for the mining sector, has just been released.

Emissions of pollutants from the raw materials sector can occur across the entire value chain, from the extraction of raw materials to the production of semi-finished products, the manufacturing of final products, waste management, and recycling processes. Pollutant emissions may originate from the combustion of fuels, e.g. at industrial facilities or during transport, from non-combustion industrial processes, or from mechanical operations such as land clearing or drilling.

Air pollutants from the raw materials industries include primary particulate matter (PM) from operations that generate dust, from fuel combustion and from specific industrial processes. PM is a complex mixture of microscopic solid or liquid matter in the air, and a key pollutant affecting human health. Depending on the size of particles, PM is classified as PM2.5 (particle size up to 2.5 μm), PM5, PM10, and so forth.

Raw materials industries also release chemical substances such as non-methane volatile organic compounds (NMVOCs). NMVOCs are a mixture of organic compounds with various chemical compositions that behave similarly in the atmosphere, emitted by combustion activities and by certain industrial production processes. NMVOC emissions can potentially form tropospheric ozone, which has a negative impact on human health.

The raw materials industries also generate substances that contribute to acidification, such as sulphur dioxide (SO2) - which originates primarily from the burning of fuels that contain sulphur-, or nitrogen oxides (NOx), mostly from road transport activities.

The sector can also emit heavy metals, which contributes to toxic deposition in soils and organisms (EEA, 2017). For instance, some cadmium and lead emissions come from the production of non-ferrous metals, and iron and steel; some arsenic originates from metal smelters and fuel combustion, and some mercury originates from iron and steel and cement production. Nickel emissions originate from nickel mining and primary production, and from steel manufacturing.

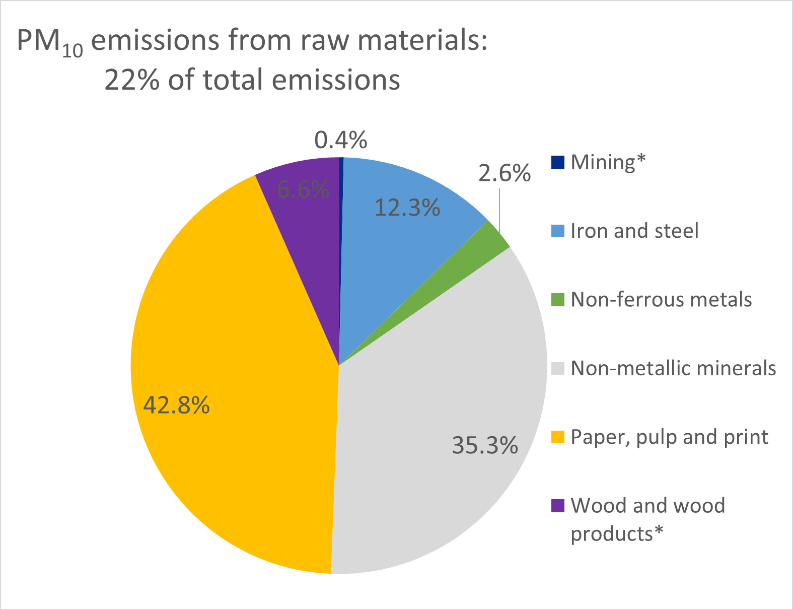

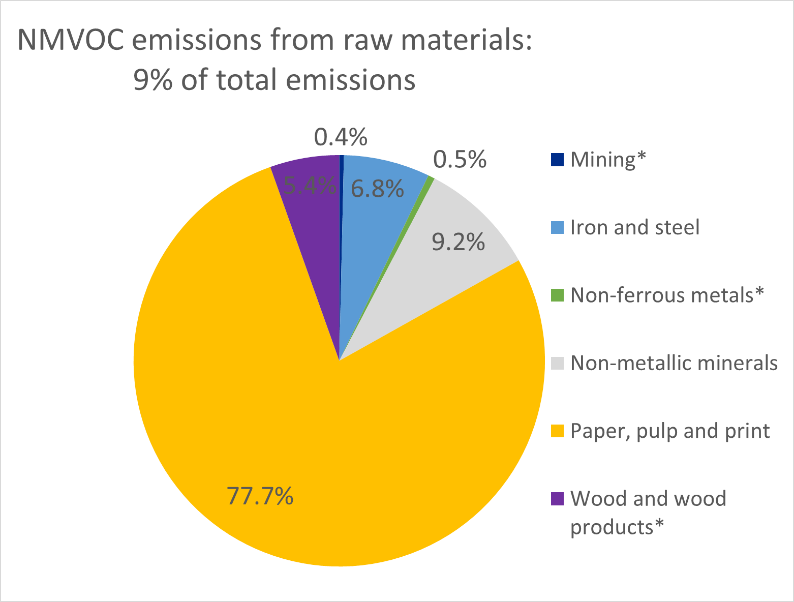

PM10 direct emissions generated onsite by the EU raw materials industrial facilities account for 22% of all PM10 direct emissions in the EU (Figure 3, top graph). A significant share of this PM10 corresponded to PM2.5, the PM fraction that is responsible for the most severe damages to human health given their greater potential to pass deeper into the respiratory system. NMVOC direct emissions generated onsite by the EU raw materials industrial facilities account for circa 9% of all NMVOC direct emissions in the EU (Figure 3, bottom graph).

Values for both PM10 and NMVOC change across Member States.

In the last few decades, the industry has made major efforts to control and reduce pollutant emissions in the EU. This includes implementing emission management plans, adopting process-integrated and end-of-pipe pollution abatement technologies, and changing fuel mixes. However, the concentration of some pollutants such as particulate matter in the air remains a major concern in some areas, in particular with regard to impacts on public health.

Direct PM10 emissions have significantly decreased in the last decades for most raw materials sectors (Figure 4 top). The production of iron and steel and of non-metallic minerals showed the most marked reductions, followed by the mining sector and the production of non-ferrous metals. However, PM10 emissions from the paper and wood industries increased, mostly due to the rise of the manufacturing of bio-based products. In addition, an increase of PM10 emissions has been observed since 2012, yet values vary across Member States.

The decreases in absolute PM10 emissions reflect the overall reduction of absolute production volumes of raw materials in the EU. Decreases were also due to efficiency improvements in most sectors. Efficiency improvements were particularly relevant for the production of iron and steel and non-ferrous metals, as well as for mining, where they were mostly associated with reductions of on-site energy requirements.

On the contrary, NMVOC emissions showed increasing trends for the raw materials sectors overall since the 70´s. The paper sector, which is the main contributor to total raw materials-related NMVOC emissions, and the wood industries showed more accentuated increases of emissions of NMVOCs than they showed for PM10. This was also due to an increase of NMVOC emissions intensity of the latter sectors. In addition, iron and steel making showed limited NMVOC emissions efficiency improvements. As for PM10 emissions, values vary across Member States.

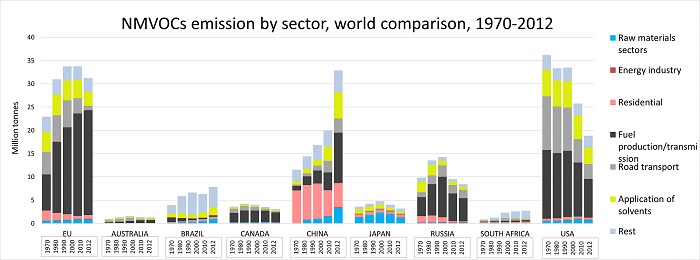

In contrast to the EU trends, PM10 and NMVOC emissions from the raw materials sector increased remarkably at a global level (Figure 5), mostly driven by the expansion of industrial production in developing economies such as China. The consumption of materials in both developed and developing countries has been a relevant driver of this expansion of the sector in developing economies.

The European Environment Agency compiles data on emissions of air pollutants (such as NMVOCs, PM, sulphur oxides and nitrogen oxides, etc.) following the reporting obligations of the Convention on Long-range Transboundary Air Pollution (LRTAP Convention). Data are available for industrial processes and product use, energy use in industry, etc.

These data give insight about the air pollutant emission trends of the raw materials industries over the last decades. Further, the Eurostat Air Emission Accounts (AEA) provide air pollutant emission data by NACE sector (from year 2008). While LRTAP emissions data follows a territory principle, AEA follow the national accounts' residence principle: emissions are accounted for even if they take place outside the EU territory, if the residence of the activity falls within the EU (for instance a shipping company operating abroad). Based on the AEA, Eurostat also estimates air pollutant emission intensities.

Scientific databases such as EDGAR provide air pollutant emission times series from year 1970 using reference data sources on emission factors and activity data. EDGAR is the data source that has been used for the graphs presented here and also in the air pollutant emission indicator of the 2018 Raw Materials Scoreboard. Emission factors are average emission rate of a given pollutant for a given source, relative to units of activity. Activity data gauges the magnitude of human activity resulting in emissions or removals taking place during a given period of time (e.g. fuel consumption, production volume).

These data sources provide air pollutant emission from direct onsite production in industrial facilities, but do not consider emissions from energy generation that takes place off site, from the production of the auxiliary inputs, or from products transport and delivery. Based on the AEA and input/output tables modelling, Eurostat also estimates the air pollutant emission from the final use of products (only the EU total aggregate), i.e. emissions embodied in products for final use, which account for pollutants emitted by sector along the full production chain of products that are consumed within the EU.

In addition to that, trends in exposure of population to pollutants (particulate matter) are also monitored by the Resource Efficiency Scoreboard and for the SDGs EU monitoring framework.

RMIS related sections

Other

- EEA, ‘Air pollution’

- EEA, ‘Air Quality Viewer’

- EC, ‘Cleaner air for all’

- EEA, ´Air pollutant emissions data viewer´

- Convention on Long-range Transboundary Air Pollution (CLRTAP)

- Gothenburg Protocol to Abate Acidification, Eutrophication and Ground-level Ozone

- EEA industrial pollution country profiles

Industrial emissions from facilities producing raw materials in the EU

The EU relies on numerous industrial facilities producing raw materials. This includes mining facilities; facilities producing intermediate products such as metals, non-metallic minerals, pulp and paper, wood and wood products; facilities manufacturing final products; and materials recovery industries (Figure 1).

At EU level, the emissions to air, water and soil of most major facilities are systematically monitored by the European Pollutant Release and Transfer Register (E-PRTR). The registry covers facilities that produce emissions above certain sector-specific thresholds, which have been set with the intention of covering significant proportions of the total mass emissions from industrial facilities. These thresholds generally depend on the production capacity of the facility. Thresholds for some mining-related activities depend on the area under extractive operation. For some specific activities, pollutants must be reported regardless of the facility’s production capacity (underground mining, metal ore roasting/sintering, etc.).

The Industrial Emissions Directive (IED) covers the largest installations producing raw materials in the EU. This directive requires facilities to adopt the so-called Best Available Techniques (BAT) to obtain the operation permit, which is managed by the competent authorities at national or sub-national level. BATs are detailed in the Best Available Techniques Reference documents (BREFs); these include standards for industrial emissions as well as for energy use, and their use is also promoted by the Circular Economy Action Plan.

BREF documents are prepared by the European Integrated Pollution Prevention and Control Bureau (EIPPCB) of the European Commission’s Joint Research Centre, and are the result of participatory processes, with full engagement by stakeholders using an evidence-based approach.

BREFs contain BAT conclusions that are given legal force by the Commission. BREFs have been adopted for several industry sectors such as iron and steel, ferrous metals processing, non-ferrous metals, cement and lime, wood-based panels, pulp and paper, glass and ceramics. In addition, a reviewed version of the BREF on Management of Tailings and Waste-rock in Mining Activities, whose standards will yet not be binding for the mining sector, has just been released.

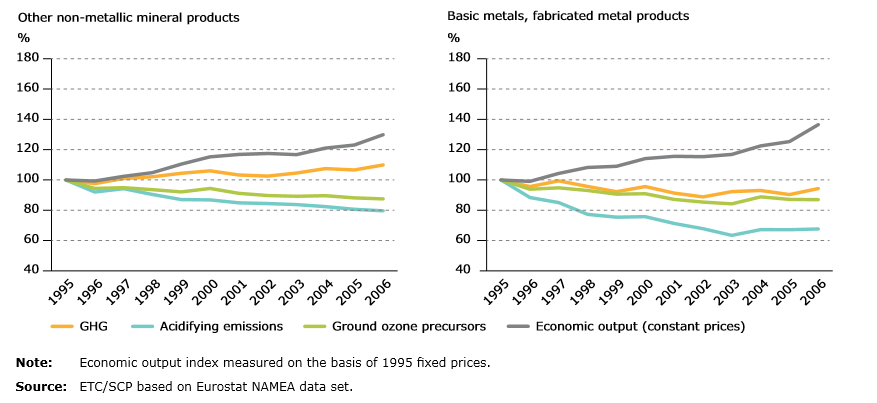

Over the past decades, EU raw material industries have made efforts to improve their environmental performance. Trends show a decrease in some environmental pressures, partly related to production levels in the sector. Improvements in efficiency have also contributed to this decreasing trend. For instance, a relative decoupling of some environmental pressures (such as acidifying emissions and ground ozone precursors) from growth in economic output has been observed in the manufacturing of non-metallic mineral products, and of basic and fabricated metals (Figure 2).

Globally, there has been a remarkable acceleration in raw materials extraction rates over the past decades. These trends, which are expected to continue, are driven by a growing population and by increasing use of raw materials per capita. Although the adoption of more efficient technologies is expanding, the demand for materials is growing faster. As a consequence, there has been a marked increase in environmental impacts associated with raw materials production over recent decades (see chapter Environmental impacts along the supply chain). Eco-innovation, resource-efficient technologies and human consumption patterns will be key determinants of demand for materials and products and their subsequent environmental impact in the future.

RMIS related sections

- RMIS Country profiles (see section `Environment’)

- RMIS Raw materials profiles (see section `Environmental and Social sustainability aspects’)

Other

- DG ENVIRONMENT, ‘Industrial emissions rules in action’

- COM(2017) 727 final, Report from the Commission to the Council and the European Parliament ‘on implementation of Directive 2010/75/EU and final reports on its predecessor legislation’

- EEA Industrial pollution country profiles

- EEA Resource efficiency country profiles

- EEA (2013), ‘Environmental pressures from European consumption and production - A study in integrated environmental and economic analysis’