Circular economy: indicators, tools and methods

You can't manage what you can't measure.

Monitoring framework

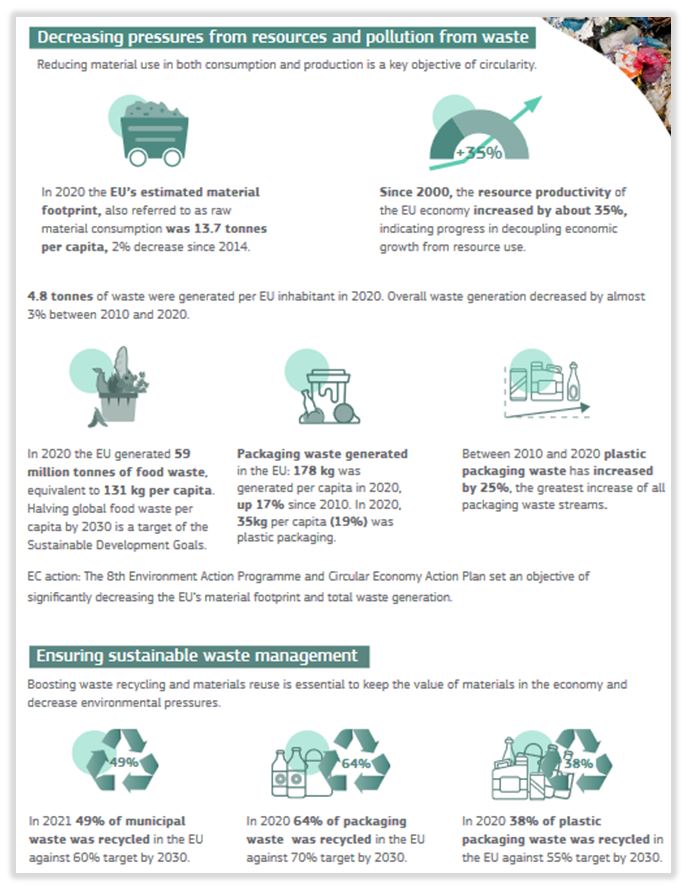

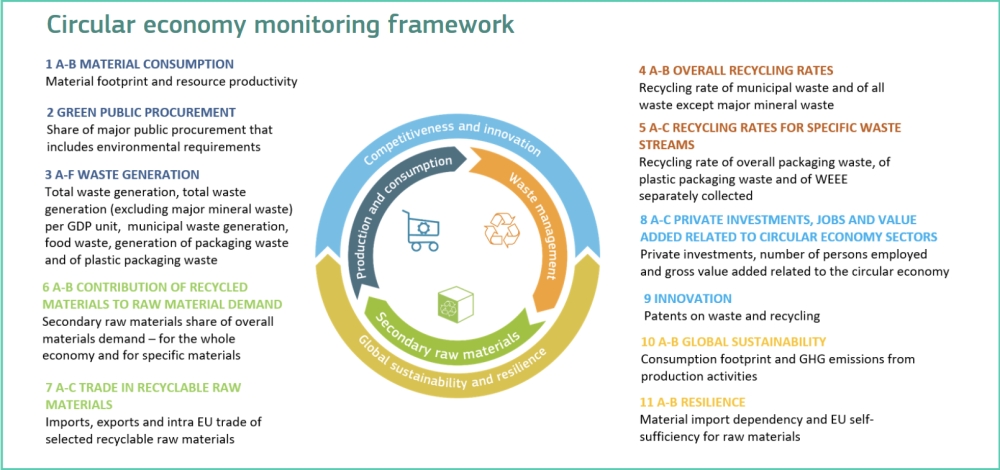

Measuring the development of a circular economy is crucial for determining the efficacy of EU policies and initiatives as well as identifying best practises. The EU monitoring framework for the circular economy has been updated in May 2023 by the Commission to include new indicators and a new component on global sustainability and resilience.

In addition to the four current dimensions of the previous monitoring framework (production and consumption, waste management, secondary raw materials, and competitiveness and innovation), the new monitoring framework also contains a new component on global sustainability and resilience. New indicators, such as the material footprint, resource productivity, consumer footprint, greenhouse gas emissions from manufacturing operations, and material dependency, are part of the new monitoring framework.

The EU monitoring framework on the circular economy is split into the following 5 thematic areas:

- production and consumption

- waste management

- secondary raw materials

- competitiveness and innovation

- global sustainability and resilience

For more details consult the information on data page and:

- Communication on a revised monitoring framework for the circular economy, COM(2023) 306

- Staff Working Document on Measuring progress towards circular economy in the European Union – Key indicators for a revised monitoring framework, SWD (2023) 306

- JRC Consumption Footprint Platform

- Circular material use rate: available here

- Material footprints in Europe: available here

- Consumption footprints: available here

- Circular material use rate: available here

- Waste generation and decoupling in Europe: available here

- Diversion of waste from landfill in Europe: available here

- Waste recycling in Europe: available here

- Material flows: Indicator 12

- WEEE management: Indicator 13

- Construction waste: Indicator 14

- Recycling: Indicator 15

Tools and methods

The effects of Circular Economy strategies including increased use of Secondary Raw materials (SRMs), can be assessed by adopting different methods, including: Material Flow Analysis (MFA), Life Cycle Assessment (LCA), and Product Environmental Footprint (PEF).

Moreover, various aspects of these methodologies can be used to measure the resource efficiency of products (REAPro - Resource Efficiency Assessment of Product).

Material Flow Analysis (MFA) is a method which allows a quantitative estimate of the stocks and flows of materials/components/products along their whole value chain within a system defined in space and time. It can help to size the effects of Circular Economy strategies on these stocks and flows.

MFA can be applied to various materials and in specific systems such as the EU system using the Material System Analyses (MSA) specifications. In addition, MFA can be applied to materials in strategic EU value-chains, like batteries. MSA studies are also used to calculate key indexes for materials that can be used to monitor the Circular Economy’s progress, in particular the EOL-RIR(End-of-life Recycling Input Rate) index.

MFA studies and results can also be used to extract meaningful indicators and knowledge that can help to better understand key value chain’s performances, also considering a forward-looking approach.

Two relevant exploratory research which apply this methodology are:

- How will second-use of batteries affect stocks and flows in the EU? A model for traction Li-ion batteries, which focuses on the potential share of secondary raw materials (e.g. Cobalt, lithium) in new batteries in the EU)

- Sustainable use of Materials through Automotive Remanufacturing to boost resource efficiency in the road Transport system (SMART), which focuses on stocks and flows of Rare Earth Elements (REE) in e-motors in vehicles.

Life Cycle Assessment (LCA) is a standardised methodology (ISO 14040) used to assess the environmental impacts of products and/or services throughout their life cycle, i.e. from the extraction of raw materials to the final disposal (including manufacturing, use phase and EoL treatments).

The communication of environment-related information is promoted by the European Commission (EC), to provide “the right incentives for citizens and public authorities to choose the most resource efficient products through appropriate price signals and clear environmental information” (Resource Efficiency Roadmap) and to “raise awareness and better mobilise key actors” (Building the Single Market for Green Products).

Hence, the recommended LCA methods by the EU to quantify the environmental impacts of products (goods or services) and organisations are the Product Environmental Footprint (PEF) and Organisation Environmental Footprint (EF) methods. Note that, for some products/organisations, Product/Organisation Environmental Footprint Category Rules (P/O-EFCRs) already exist.

The EC, through its DG Environment and JRC, also has established the European Platform on Life Cycle Assessment (EPLCA) to increase the availability of quality life-cycle data and methods on LCA.

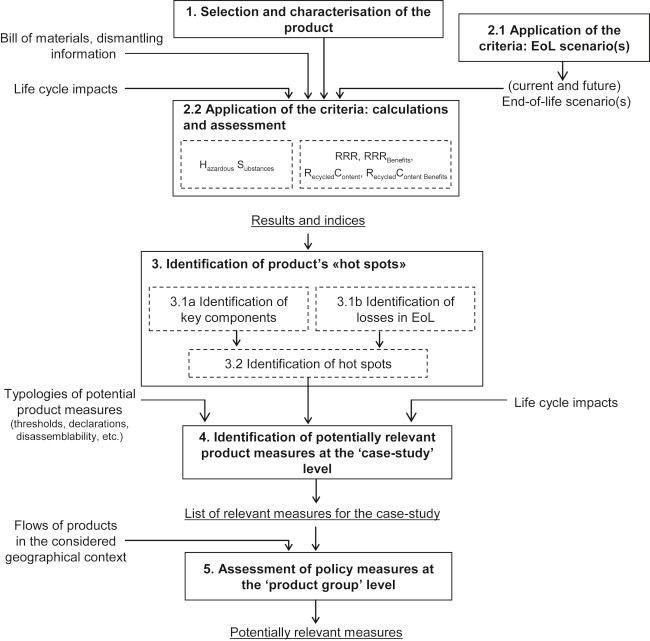

Based on a Life Cycle approach, the Joint Research Centre developed and applied a method named Resource Efficiency Assessment of Products (REAPro) to support discussions related to circularity and material efficiency in the context of product policies.

Even though developed to support discussions in the context of product policies (especially steps 3 and 4, in the figure), REAPro can be adapted to other policies (e.g. waste policies, raw material policies) and industrial processes, e.g. it has already been applied to assess the environmental performances of open-loop and closed-loop recycling options for plastic waste flows in a Member State.

The main criteria for resource efficiency investigated within the REAPro method included:

The REAPro method has been applied to several case-study products in the context of the Ecodesign Directive and Ecolabel regulation belonging to Electrical and Electronic Equipment, as:

Latest update: 30/05/2023

Authors: Silvia Bobba, Fernando Coelho, Fabrice Mathieux