Environmental impacts along the supply chain

The production of raw materials and derived products takes place along different stages, often occurring in multiple locations. This leads to different types of environmental impacts.

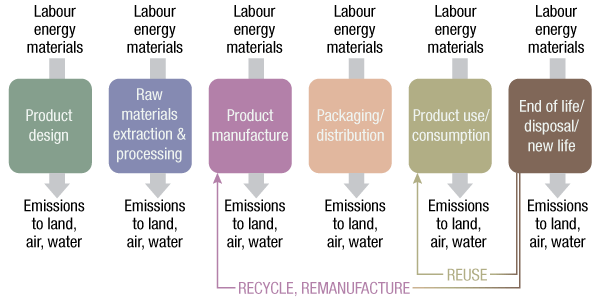

The supply chain starts with a product’s design, and continues with the extraction of the required materials (e.g. bauxite, iron ore or wood), transport and subsequent processing to yield semi-finished products such as steel or planed wood (Figure 1). The supply chain continues with the manufacturing of final products (e.g. machinery, furniture or vehicles), and their distribution and use. All these stages lead to environmental impacts, which will depend on, for example, the material and energy inputs required and the resulting emissions and waste streams.

In addition, products may be managed in various ways when they reach their end of life: they may be reused, recycled, used for energy recovery, or disposed of, which will have different impacts on the environment. For a sound comparison of alternative ways of production (e.g. different techniques/technologies, energy inputs, materials sourcing, etc.), the environmental impacts along the whole materials life cycle need to be accounted for: the so-called ‘cradle-to-grave approach’.

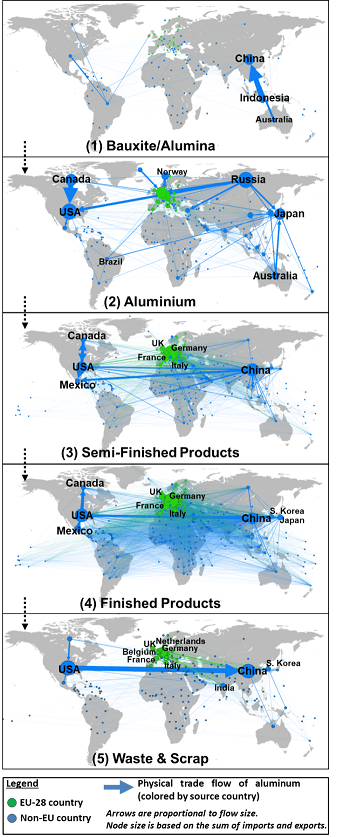

Raw materials’ markets are global in nature. Therefore, the physical trade in raw materials at different production stages builds complex and often interlinked supply networks (Figure 2 shows an example for aluminium). This means that raw materials usually flow across several countries. In this context, a sound estimate of the environmental impacts of supply chains needs to account for the transport of materials and products, often over long distances. In addition, environmental performance can vary significantly between locations, due to different production techniques and technologies, combustion of different fuels, etc. This will determine the ultimate environmental impacts on the local and global environment.

Types of environmental impact

Environmental impacts along raw materials supply chains are caused by, for example, the use of resources and the emission of pollutants to the environment. For instance, land uptake by mining facilities can contribute to biodiversity loss; mine tailings can lead to water acidification; industrial processes (e.g. calcination in cement production) or the combustion of fuels generate greenhouse gases that contribute to global warming (Figure 3). These impacts can affect ecosystems and human health, and may be local or global in nature. An additional impact of raw materials production is contribution to the dispersion or dissipation of natural, non-renewable resources (such as minerals or fossil fuels).

Environmental impacts associated with mining and the production of biotic materials (pulp, natural rubber, etc.) have some distinctive features. At mining facilities, pollution is usually more diffuse, and environmental impacts frequently continue during the post-closure phase. In the case of biotic products, sustainable harvest rates can guarantee renewal of the resource. However, growing and harvesting biotic materials can also cause a number of specific impacts on the natural ecosystem.

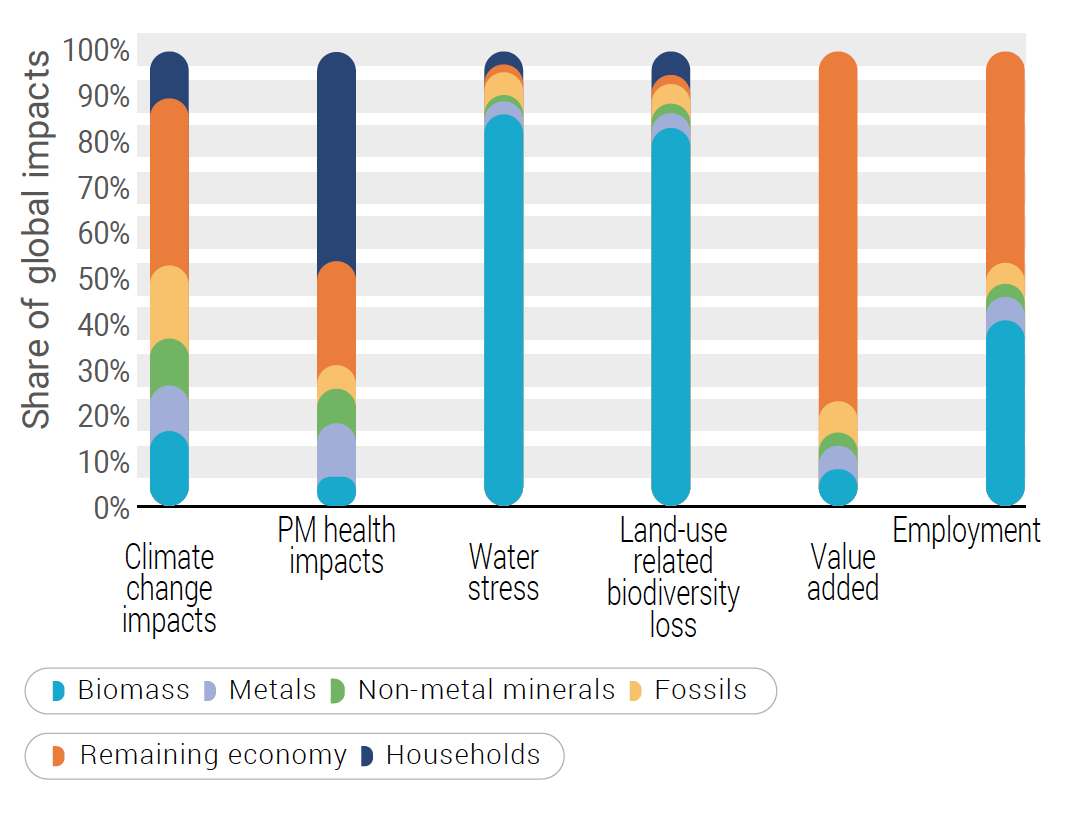

The extraction and processing of raw materials accounts for significant shares of the total global environmental impacts, especially for some impact typologies (Figure 4). An example for this are climate change and particulate matter (PM) impacts from metals and non-metallic minerals extraction and processing.

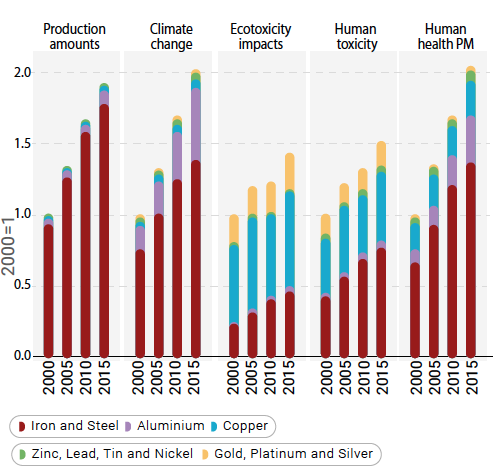

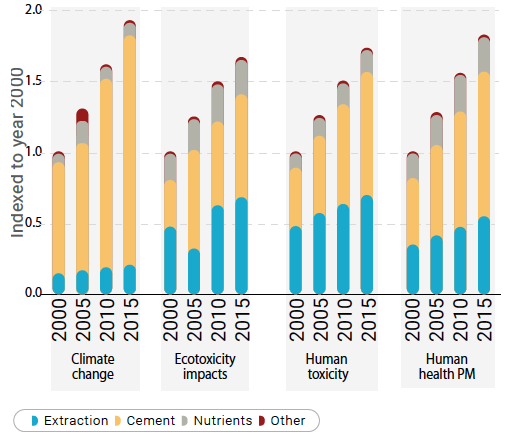

Impacts have also changed over time. Between 2000 and 2015, the climate change and PM health impacts of metals extraction and processing almost doubled (Figure 5 top). Toxicity impacts also increased in the same period, but at a slower pace. Significant increases were also observed for non-metallic minerals (Figure 5 bottom).

The type and intensity of environmental impacts depend on the intrinsic features of the commodity being produced; the technologies, techniques and management practices in place; and the environmental and socioeconomic framework conditions. As an example, the impact of a mining facility on water will depend on the specific water requirement for mineral extraction and processing, the level of water reuse and depuration at the facility, and local water availability.

The environmental impact associated with the production of one unit of commodity (e.g. 1 kg) varies significantly between commodities; it can be very high in some cases (Table 1). However, some materials with lower environmental impact per mass unit may emerge at the top of the overall total environmental impact ranking, due to the large volumes of materials being produced (Table 1). For instance, this is the case for base metals such as iron or aluminium.

| Ranking | Impact per kg primary metals |

Impact global production primary metals |

| 1 | Palladium | Iron |

| 2 | Rhodium | Chromium |

| 3 | Platinum | Aluminium |

| 4 | Gold | Nickel |

| 5 | Mercury | Copper |

| 6 | Uranium | Palladium |

| 7 | Silver | Gold |

| 8 | Indium | Zinc |

| 9 | Gallium | Uranium |

| 10 | Nickel | Silicon |

Environmental impacts from use and at the end of life

Raw materials can be embodied into products or be used along the production chain in very different quantities and qualities. Due to the complexity of material applications, assessment of the environmental impact associated with the production of a material usually accounts for stages from extraction up to the manufacturing of semi-finished products (e.g. plain wood or aluminium). This approach is known as ‘cradle-to-gate’, and it accounts for neither the impacts of the manufacturing of the final products and their use phase, nor for the environmental impact once products reach their end of life.

However, it is worth noting that the replacement or substitution of specific materials in products can lead to improvements in a product’s environmental performance during the use phase. An example is the use of aluminium in the automotive sector, which can reduce the weight of the vehicle and therefore the energy consumption during the use phase.

In addition, the way products are managed when they reach their end of life can significantly affect their total environmental impacts. With this in mind, products can be designed in a way that maximises their potential reuse and recycling (so-called ‘design for recycling’). The 2015 Circular Economy Action Plan established a concrete and ambitious programme with measures for ‘closing the loop’ in the life cycle of products. It aims at boosting repair, reuse and recycling, which generally (although not always) can improve the environmental performance of the production chain. Moreover, the 2020 Circular Economy Action Plan intends to further boost circularity in production processes and enhance waste policies. Closely linked to these aspects, regulation on Eco-design establishes requirements for the design of resource-efficient products and aims to reduce energy requirements and improve the material efficiency of energy related products (e.g. household appliances, information and communication technologies, or building and engineering products).

Environmental impacts from accidents

Apart from the environmental impacts associated with facilities under ‘normal’ operation, accidents may also occur. For instance, failures of mining tailing dams may be considered the events with the largest of all environmental impacts related to mining (STRADE, 2016). Spills due to maintenance problems, or unexpected discharges due to human error may also occur. Accidents may be more likely to occur under specific framework conditions such as higher tectonic activity or heavy rainfall.

Accidents are not accounted for in environmental impact life-cycle assessment. These can be addressed instead through environmental management systems or Environmental Impact Assessment.

Additional references

RMIS related sections

- RMIS Country profiles (see section `Environment’)

- RMIS Raw materials profiles (see section `Environmental and Social sustainability aspects’)

Resource use

- EEA (2013), ‘Environmental pressures from European consumption and production - A study in integrated environmental and economic analysis’

- UNEP (2019), ‘Global resources outlook’

Environmental impacts

- Dolega, P., Degreif, S., Buchert, M. et al., 2016, ‘Outlining Environmental Challenges in the Non-Fuel Mining Sector’, STRADE Policy Brief No 04/2016. Darmstadt

- MMSD (2002), ‘Mining, Minerals and Sustainable Development’

- UNEP (2013), ‘Environmental Risks and Challenges of Anthropogenic Metals Flows and Cycles’

- Santero, N. and Hendry, J. (2014), ‘Harmonization of LCA methodologies for the metal and mining industry’, The International Journal of Life Cycle Assessment 21, issue 11, 1543–1