Water

Water is an essential input to the economy and to life. Safeguarding its supply and quality is crucial for citizens and for the health of ecosystems. Water is also an essential input to the raw materials extractive and manufacturing industries, being used in ore processing, dust suppression, cooling processes, and as a material input for most industrial processes.

Although water can be reused multiple times at facilities, some raw materials industries can be water-intensive, and this can significantly reduce water availability at the local level. In turn, water stress may put the security of supply of some raw materials at risk, when water supply for production is not guaranteed.

Apart from water-volume related aspects, discharges from the raw materials industry and run-off from mining sites can affect the quality of water bodies and soils. Extractive practices in the seabed and deep sea can also impact coastal and marine ecosystems.

This section consists of several sub-sections covering all the aspects mentioned above. In addition, a dedicated sub-section describes the datasets available on water use and emissions to water and policies safeguarding water.

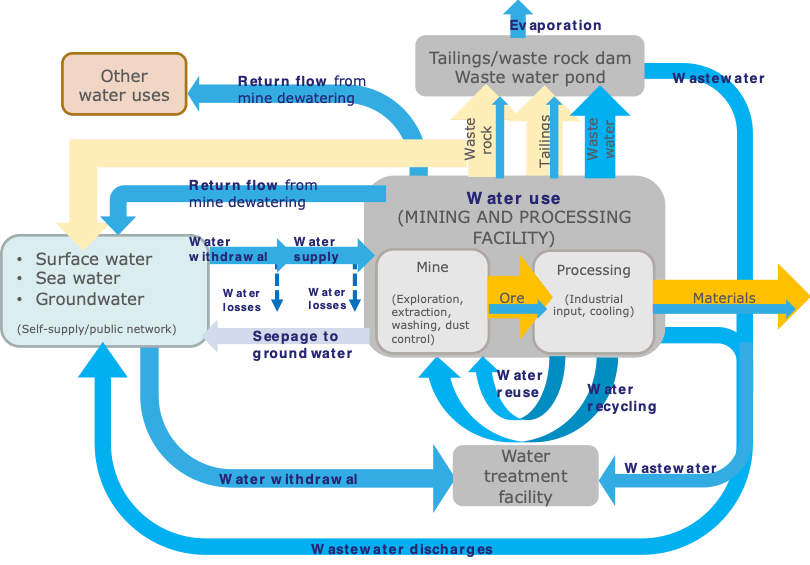

Raw materials industries need the right amount of water, at the right moment and of the required quality. To this end, mining and processing facilities often rely on self-supply of water, which may come from local water bodies, groundwater or the sea (Figure 1). Water may also be supplied through the public network. In the specific case of mining operations, additional water resources are usually available from mine dewatering, which often satisfies the facility’s requirements and may also provide additional resources for other water users. As a drawback, dewatering may lead to drawdown of the water table under certain circumstances.

Depending on the water quality requirements for the mining and industrial processes, water supplies may require pretreatment. After water has been used, the resulting wastewater is treated and discharged into the environment. Facilities may set up various types of dedicated ponds and dams for wastewater management. Often, wastewater is reused and/or recycled and loops back into the facility for processes that are less demanding in terms of water quality (cascading use).

The EU is quite advance in terms of water management at mining and other industrial operations. More recently, the sector can also learn from other countries ahead, with advance applications and regulation for e.g. desalinated seawater.

In addition to the direct use of water at the facility, the production of raw materials relies on the use of auxiliary materials for onsite production (such as chemicals), on technical equipment, and often on energy supplies that are produced off site. The production of all these items requires additional water inputs.

In order to safeguard water resources, the Water Framework Directive (WFD) establishes quality objectives for water bodies, and specifies the need to establish River Basin Management Plans and reporting obligations on water-related data.

Water use and wastewater discharges are also regulated by the Industrial Emissions Directive. This directive covers the largest installations producing metals and minerals, and part of the wood sector, and requires adoption of the so-called Best Available Techniques (BAT), detailed in the Best Available Techniques Reference documents (BREFs). BREFs include standards for water use and water discharges by industrial processes. A number of BREFs exist for sectors such as iron and steel, wood and ceramics, and others are under development.

In parallel, the EU Roadmap to a Resource Efficient Europe highlights the need to promote water efficiency, and declares that it could be significantly improved based on technological innovation. Boosting water reuse and recycling, in a context of increasing water scarcity problems, is also promoted by the Circular Economy Action Plan, which further promotes implementation of the BREFs standards.

In addition, at Member State level, water protection restricts mining activity by the designation of no-go areas in most countries, or in other ways such as limiting the depth of extraction in some open pit mines (Czech Republic, Austria), or prohibiting the exploitation in the riverbed (Romania) or around water springs (Serbia) (Minatura Deliverable 3.1, 2016).

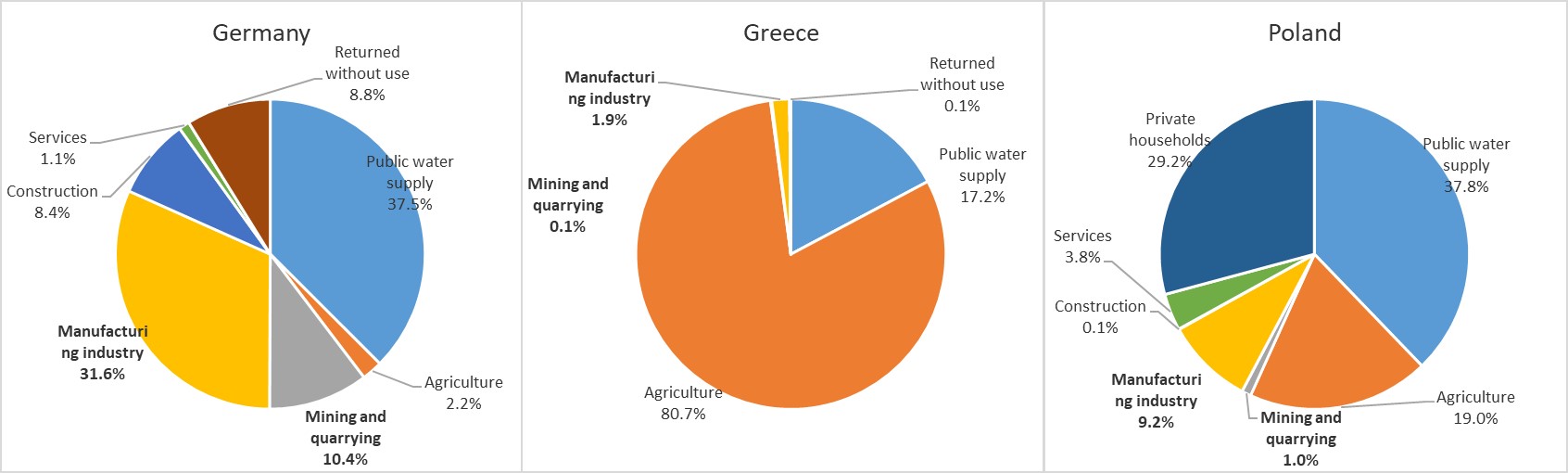

Direct water withdrawal by facilities extracting and processing raw materials is generally relatively small, compared to other economic activities such as agriculture or public water supply (Figure 3). Depending on the commodity mined, a significant proportion of the water withdrawn may return to the environment without major alterations to quality. At mining sites and in the manufacturing sector, water consumption is usually well below water withdrawal volumes, due to circular use of water within the facility. However, water uptake by the sector can still markedly influence water availability at the local level, although figures vary widely between countries.

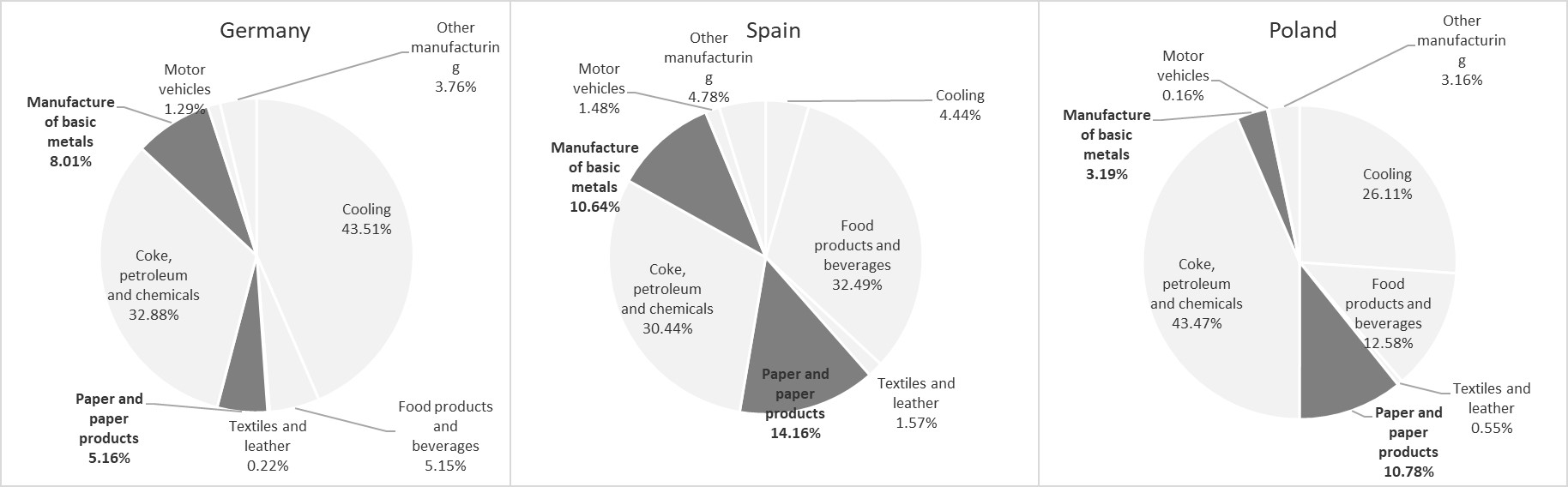

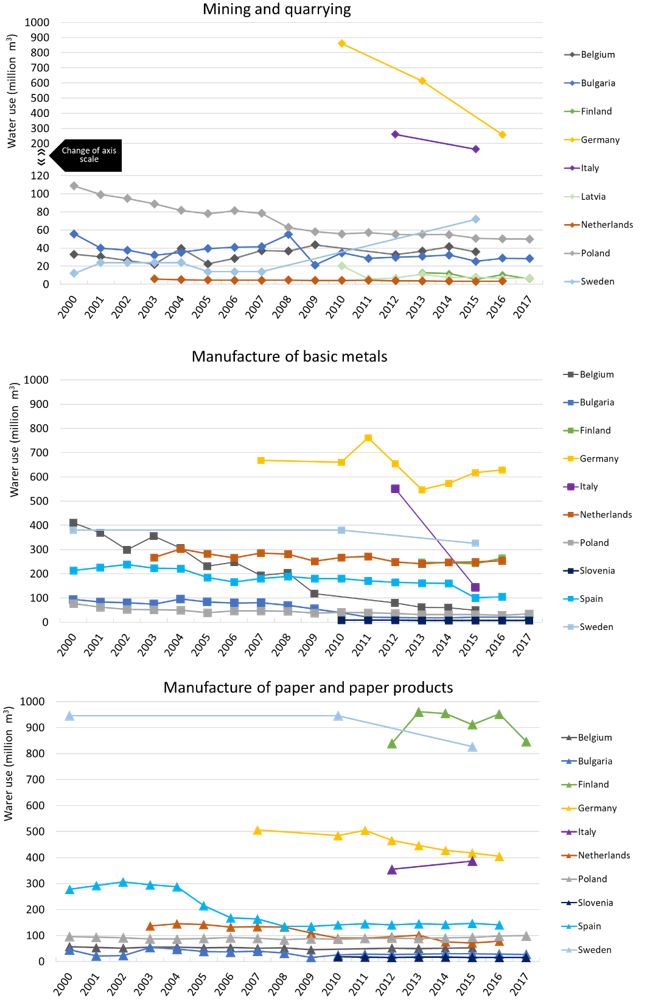

Among the raw materials manufacturing sectors, the production of basic metals such as steel, and of paper and paper products, typically use significant amounts of water (Figure 4).

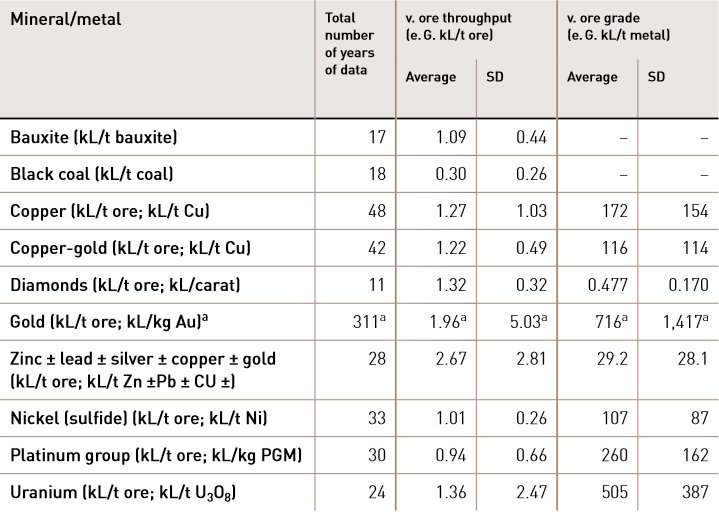

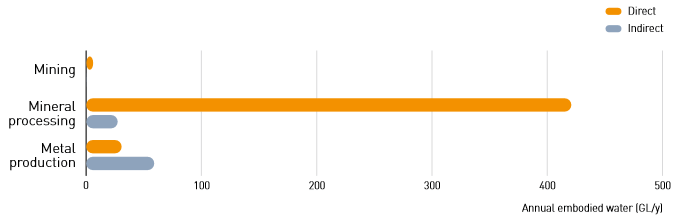

Within the raw materials sector, water requirements per unit of production are highly industry-specific. For instance, the extraction of precious metals and the manufacture of iron, steel, and paper are typically water-intensive activities. The manufacture of wood and of non-metallic minerals are usually less demanding of water. Particularly variable are the water requirements for mineral processing (Table 1), where water consumption also varies greatly between production stages (Figure 5).

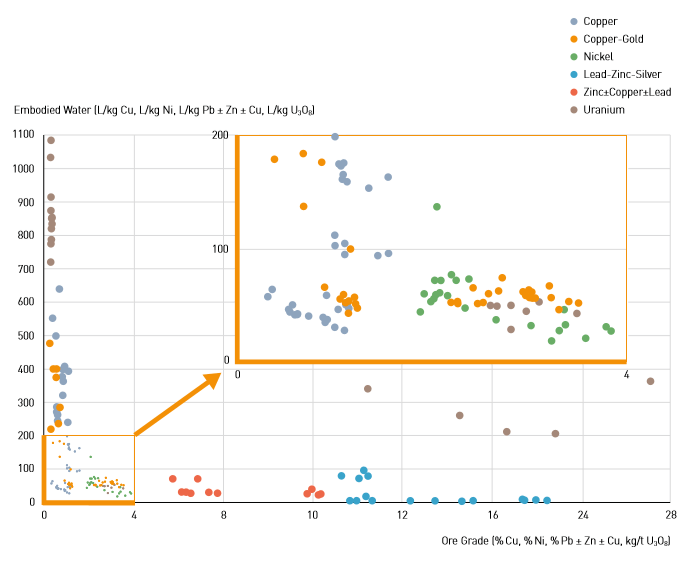

Water requirements for processing a specific commodity can vary greatly between locations and depending on the mineral concentration in the ore (Figure 6). In regard to the latter, a current challenge to further improvements in water efficiency at mining sites is the decreasing trend in ore grade, which means further processing is required to extract the mineral, with a subsequent increase in water demand.

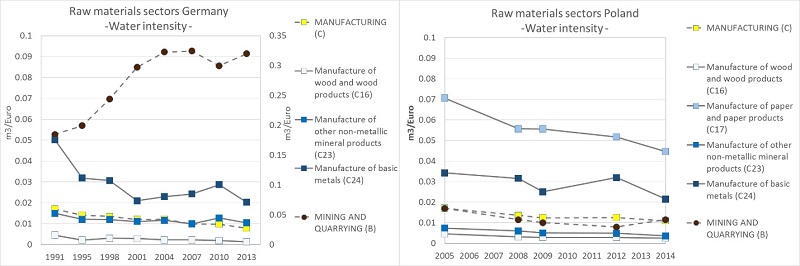

There is evidence of overall decreasing trends in several raw materials sectors in the first half of the 2000´s, while trends are more varied in the second half (Figure 7). In the last years, water use for basic metals manufacturing increased in some countries, while less water was used by the paper industry and mining and quarrying. Increases generally took place in locations with no water stress (see also Figure 7).

These trends seem to be closely linked to production volumes, but also to improvements in water efficiency in some sectors (Figure 8), for instance increasing rates of water reuse and recycling. Volumes of wastewater discharge followed the decreasing trends in water withdrawal in the mining and quarrying sector, and show very noticeable decreasing trends overall. Indeed, the raw materials industry claims to have made strong efforts to reduce water use and wastewater discharge over recent years through, for example, improvements in water reuse (CEPI, 2014). The implementation of industrial and water policies has contributed to such improvements, especially those policies pushing towards increasing rates of wastewater treatment.

Water availability influences the capacity of the raw materials sectors to supply materials in a secure manner. Indeed, water availability (often closely related to water price and therefore production costs) can be a decisive factor in determining the location of an operation site in water-scarce environments or in locations where there is strong competition with other uses such as agriculture, households or tourism. Depending on national or subnational regulations, under water stress conditions, water supply to industry is usually not given priority over other uses such as supply to households.

In this context, the Framework for Responsible Mining explains that the mining industry has been at the forefront in water conservation, since companies recognise that decreasing water consumption is closely linked to decreasing processing costs, as well as to the ability of a company to operate during dry periods. However, there are growing concerns worldwide about the risk of water stress, which may result in disruptions to production, including in the raw materials industries. Indeed, water withdrawal for industrial use and for other purposes is projected to increase significantly in the next decades.

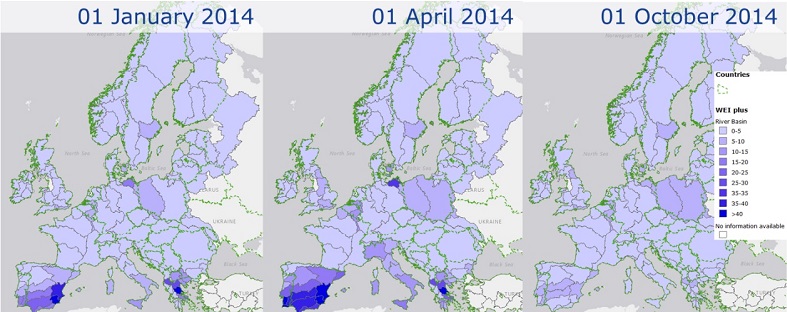

Although the use of water resources can be considered sustainable in the long term in the EU overall, specific regions in southern Europe already face water stress problems (Figure 9). Information on risks to raw materials production related to water scarcity and to other considerations is available in the ´Environmental and social sustainability aspects´ section of the RMIS country profiles.

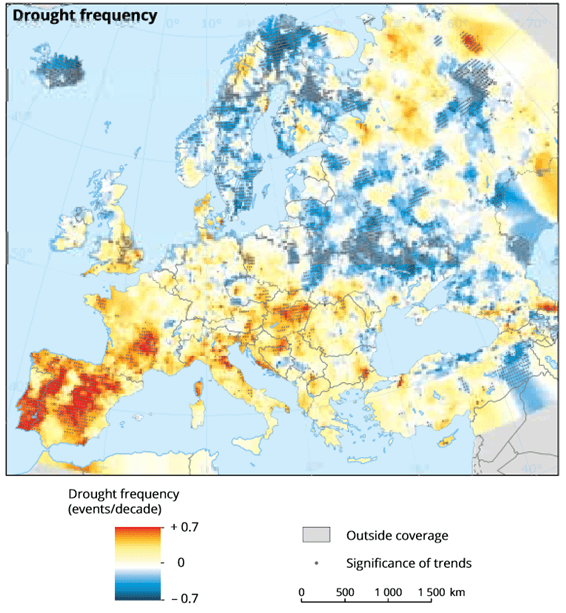

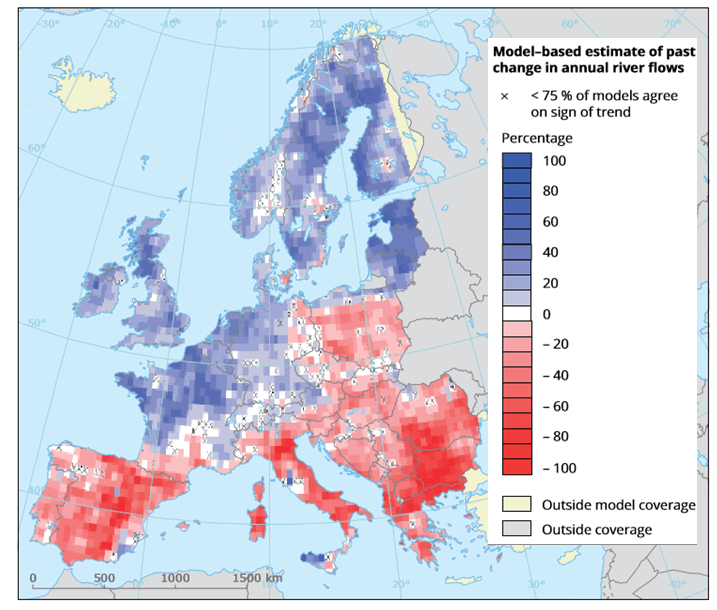

Water stress problems are likely to accentuate under the effects of climate change and will require adaptation of the sector. For instance, in the past decades, the frequency of droughts has increased, especially in south-western and central Europe (Figure 10). The annual flow of rivers has also decreased considerably, especially in southern and parts of eastern Europe (Figure 11), some of which were already water-scarce areas for at least some periods of the year. Moreover, climate change is projected to significantly change the seasonality of river flows across Europe; summer flows are projected to decrease overall, even in the regions where annual flows are forecast to increase.

On the other hand, trends in many water-abundant areas have been the opposite: in some of these regions, water has become more abundant and flooding episodes have increased. This situation may lead to increasing needs for dewatering at mining sites.

In addition to aspects related to water volume, discharges from the raw materials industries can affect the quality of water bodies and soils. These industries can release nutrients (e.g. nitrogen, phosphorous), metals and heavy metals into water. Toxic effluents and leakages from waste management or storage facilities may penetrate groundwater resources, which are essential sources of clean water in many European areas. Pit lakes, which may originate from relief alteration caused by extractive activities, can also cause similar impacts (STRADE, 2016). The treatment of e-waste illegally shipped in developing countries is often managed using rudimentary techniques, causing environmental and health-related impacts.

While manufacturing industries are generally ‘point’ pollution sources, water pollution at mining facilities is generally also ‘diffuse’. For instance, acid mine drainage (AMD) from sulphide minerals can have extensive impacts on water and soil quality. AMD, which is one of the main soil and water-related problems of mining activities, occurs when sulphide minerals react with oxygen and water, leading to the formation of sulfuric acid forms, which can dissolve e.g heavy metals. In addition, chemicals used for processing such as cyanide or nitrogen-compounds, ore elements and tailings sludges can further contaminate water and soils, and even lead to high concentrations of toxic reagents and heavy metals in groundwater when leakages from tailing ponds occur (STRADE, 2016).

In addition, accidents still occur, both in developing and developed countries, and they can be responsible for the biggest impacts on water and soils. Accidents are mostly due to heavy rainfall and seismic activity (however, operation and design mistakes are also responsible for that) (STRADE, 2016).

Data on pollutant emissions from major industrial facilities show that metal production is a major contributor to the release of heavy metals such as lead and nickel, while mining releases significant volumes of heavy metals such as lead, copper and zinc. Most copper and zinc originates from underground mining and related operations. The release of substances is generally concentrated in a small number of facilities, especially for some pollutants in mining facilities. Paper and wood production industries are the second largest industrial contributors to the release of total organic carbon (TOC) to water, plus significant amounts of zinc.

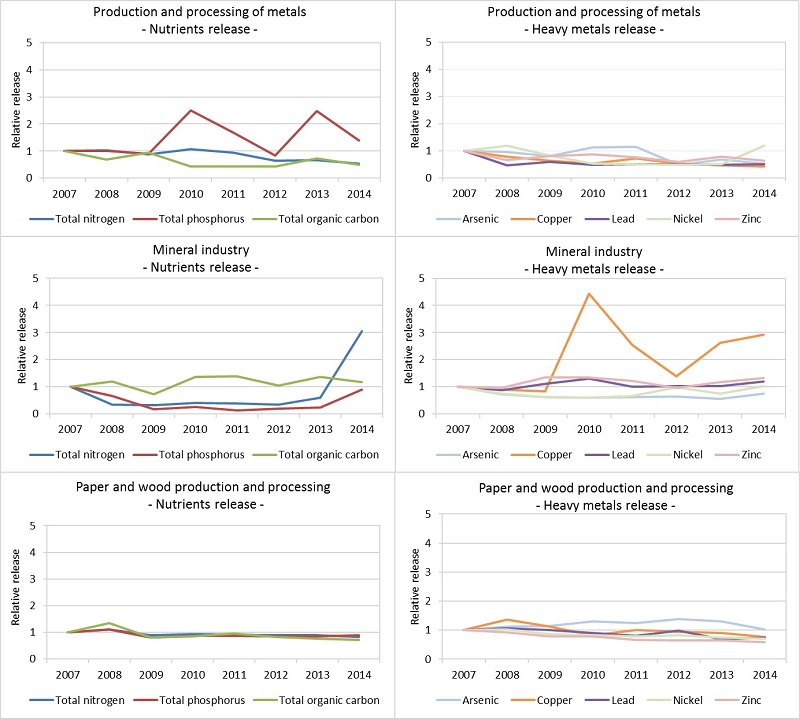

Pollutant releases from the metals industry have decreased overall, except for an increase in nickel (Figure 12), which can originate both from (coal-based) power generation and from metal processes themselves. For the mineral industry, emissions have increased overall (especially for copper in eastern Europe, from open-cast mining), yet they show very variable trends. Paper and wood production showed very stable trends for nutrient releases, and overall decreasing trends for heavy metals - except for arsenic, which can for example originate from the burning of fossil fuels. This trend took place in the context of generally decreasing trends for lead, zinc, nickel and TOC for the whole set of major industrial facilities (as reported to E-PRTR), and increasing trends for copper.

The implementation of industrial and water policies has already led to significant improvements in terms of water reuse and the control of wastewater discharges by industries. Simultaneously, these policies have also led to limitations, for example on some mining activities, since a site cannot be moved to a different location when local water-related issues arise.

In the mining sector, the prevention of water contamination is an important part of mine operation and closure. At many mines, control systems have been implemented, as required by regulation. However, many of the water impacts from mining may occur post-closure. In fact, ‘abandoned and historic mining’ is one of the water pollution sources listed in the Water Framework Directive inventory of emissions, discharges and losses.

Increasing attention is being paid to marine and deep-sea mining. This type of mining refers to the extraction and processing of abiotic resources in the seabed, for instance minerals, metals or aggregates such as limestone or gravel. It also encompasses the extraction of minerals dissolved in seawater.

The exploitation of mineral resources from the ocean is already taking place, and is one of the focus areas of the EU Communication on Blue Growth. While current activity focuses on shallow water, minerals other than sand and gravel have just started to be exploited and mined from the sea. The Communication states that by 2020, “5 % of the world's minerals, including cobalt, copper and zinc could come from the ocean floors. It may also become economically feasible to extract dissolved minerals, such as boron or lithium, from seawater.”

Deep-sea mining, i.e. seabed mining in deep ocean areas, is thus seen as a potential source of minerals to ensure a secure supply for EU industries, since the ocean crust contains mineral-rich deposits and technologies for extraction are rapidly improving. Examples of valuable mineral deposits are cobalt-rich crust, polymetallic manganese nodules and polymetallic massive sulphides.

Numerous organisations within the EU are engaged in seabed mining activities, both as technology providers and as mine operators, yet the sector is still small. The European Commission is considering this practice for areas located under national jurisdiction but also outside it, since most opportunities are in non-EU waters. In this context, the International Seabed Authority, which is responsible for monitoring all mineral-related activities, is finalising the adoption of rules that will permit states or organisations to extract minerals in areas outside their national jurisdiction.

The environmental impacts of deep-sea mining are still under study and subject to debate. Impacts will depend on the typology of the deposit and the extraction techniques put in place. Some of the expected impacts are those associated with pollution by ships onto surface water, and from the dewatering of slurry on board, where the excess water will be returned to the water column at a predetermined depth. To this regard, and following the precautionary principle, the EU Biodiversity Strategy for 2030 states that, in international negotiations, “the EU should advocate that marine minerals in the international seabed area cannot be exploited before the effects of deep-sea mining on the marine environment, biodiversity and human activities have been sufficiently researched, the risks are understood and the technologies and operational practices are able to demonstrate no serious harm to the environment”. The European Commission is also engaged in the development of studies and projects aimed at gaining a deeper understanding of the possible benefits and drawbacks of this deep-sea mining.

Dredging is another practice affecting the quality of water bodies. It is defined as the removal of sediments or contaminated deposits from the bottom of water bodies (lakes, rivers), harbours, etc. In the EU, the main volume of sediments is dredged from coastal areas, most of which are not contaminated. The associated mobilisation of materials, which may include hazardous substances, can have significant impacts on aquatic ecosystems. There are numerous guidance documents to prevent this and other types of impact, such as Dredging Management Practices for the Environment.

Although not fully complete, Eurostat collects and harmonises data on water use by the industry, based on data reported by Member States, which cover some raw materials sectors. These data has been used for the analysis of water use in the 2018 Raw Materials Scoreboard. More complete data series are available directly from national statistical offices and/or competent bodies. In addition, the European Pollutant Release and Transfer Register (E-PRTR) provides data on pollutant emissions to water from major EU industrial facilities, which also include the raw materials industry. In the case of mining, the International Mine Water Association (IMWA) gathers research from worldwide experts in the field.

Private companies also disclose some water-related data, although reporting schemes and studies are still highly heterogeneous. Examples include disclosures on water withdrawal, consumption and discharges in the Global Reporting Initiative and the CDP water programme, both of which also cover raw materials production companies.

Water use in the sector is also approached from a life cycle perspective, through water footprinting in line with ISO water footprint guidance. This approach considers not only direct water used onsite, but all water used along the production chain (from extraction to transport and production). Materials associations such as the World Steel Association or European Aluminium have also undertaken life cycle studies, with figures provided on water inputs and outputs.

Finally, the EU major accident reporting system (MARS), established by the EU’s Seveso Directive, provides data on major accidents, near misses, etc. aggregated by type of economic activity. However, the completeness and sectoral aggregation of the information limits the usability of these data for monitoring the sector.

Direct water use

- EEA, ‘Use of freshwater resources in Europe’

- Zal, N., Bariamis, G., Zachos, A., Baltas, E., Mimikou, M., (2017). ‘ETC/ICM Technical Report 1/2017: Use of Freshwater Resources in Europe 2002-2014. An assessment based on water quantity accounts’.

Emission to water

- EEA Industrial pollution country profiles

- Van den Roovart, J., van Duijnhoven, N., Fribourg-Blanc, B., Siauve, S., Prchalova, H., 2017, ‘ETC/ICM Technical Report 3/2017: Emissions of pollutants to Europe’s waters — sources, pathway and trends’.

Good practices

- Best Available Techniques (BAT) reference documents

- ICMM (2012), ‘Water management in mining: a selection of case studies’

- ICMM (2014), ‘Water stewardship framework’

- ICMM (2017), ‘A practical guide to catchment-based water management’

- CSP (2005), ‘Framework for Responsible Mining: A Guide to Evolving Standards’

- European Innovation Partnership (EIP) on Water

- DG ENVIRONMENT, ‘Water reuse’